Introduction

The advent of robotics has revolutionized engineering, paving the way for unprecedented innovation, efficiency, and precision across various sectors. From manufacturing to healthcare, robotics plays a pivotal role in enhancing productivity, safety, and quality. This article explores the multifaceted role of robotics in modern engineering, examining its applications, benefits, challenges, and future prospects.

A Historical Perspective

The integration of robotics into engineering is not a recent phenomenon. The first programmable robot, Unimate, was deployed in 1961, ushering in a new era of automation. Since then, advancements in artificial intelligence (AI), machine learning, and sensor technology have transformed robots into sophisticated tools capable of performing complex tasks. Today, the scope of robotics extends well beyond assembly lines to include areas such as research, logistics, and even building infrastructure.

Applications of Robotics in Engineering

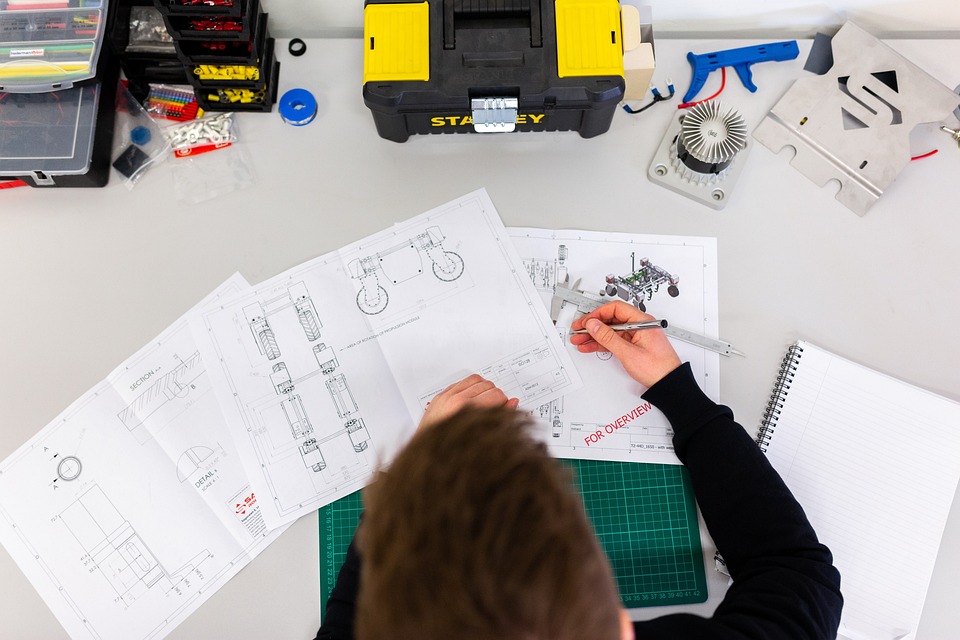

1. Manufacturing and Automation

Robotics has its roots in the manufacturing sector, where automated machines now perform repetitive tasks with precision and speed. Robotic arms, CNC machines, and conveyor systems have streamlined production processes, reducing labor costs and minimizing errors. Techniques like 3D printing have further augmented manufacturing capabilities, allowing for custom designs that were previously unattainable.

2. Construction

In the construction industry, robotics is reshaping the way structures are built. Drones provide aerial surveys for site assessments, while robotic bricklayers and 3D printers can construct walls and buildings more efficiently. These technologies increase safety by minimizing human exposure to dangerous sites and enabling advancements like modular construction, where sections are built off-site and assembled on location.

3. Healthcare

The medical field has seen a remarkable transformation thanks to robotic technology. Surgical robots, such as the da Vinci Surgical System, allow for minimally invasive procedures with enhanced precision. Robotics also plays a role in rehabilitation, where robotic exoskeletons assist patients in regaining mobility. Moreover, robots in hospitals enhance workflows by delivering supplies and managing logistics, improving patient care.

4. Transportation

Autonomous vehicles are at the forefront of the transportation revolution. Engineering innovations in self-driving technology aim to improve safety and efficiency on roads. From personal vehicles to commercial transportation systems, robotics is enhancing logistics through automated fleet management.

5. Aerospace and Defense

In aerospace engineering, robotics is integral for both design and manufacturing processes. Unmanned aerial vehicles (UAVs) have become vital for surveillance, reconnaissance, and even delivery. Robotics also plays a critical role in defense applications, such as bomb disposal and reconnaissance missions, where human presence can be risky.

Benefits of Robotics in Engineering

1. Increased Efficiency

Robots operate at remarkable speeds and can work tirelessly, significantly increasing production rates and reducing lead times. The efficiency of robotic systems translates to lower operational costs for businesses, promoting competitive advantages.

2. Improved Precision and Quality

Robots exceed human capabilities in precision tasks, ensuring higher quality outputs. Their ability to work in controlled environments reduces variability and defects, enhancing overall quality assurance.

3. Enhanced Safety

In industries characterized by hazardous environments, robotics helps to mitigate risks. By assuming dangerous tasks, robots protect human workers from injury or exposure to harmful substances.

4. Data Collection and Analysis

Robots equipped with sensors can gather vast amounts of data, which can be analyzed to improve processes and predict trends. This data-driven approach enables engineers to make informed decisions, optimizing production and reducing waste.

Challenges Facing Robotics in Engineering

1. High Initial Investment

While the long-term benefits of robotics are substantial, the initial costs can be prohibitive for smaller companies. Investing in robotic systems requires careful consideration and planning.

2. Workforce Displacement

The rise of automation poses challenges for the workforce. As robots take over repetitive tasks, there is a legitimate concern about job displacement. Transitioning workers into new roles that complement robotic technology is critical for maintaining employment levels.

3. Technical Limitations

Despite advancements, current robotics still face limitations in adapting to unpredictable environments. Engineering solutions that allow robots to learn and adapt in real-time remain a key area of research.

Future Prospects

The future of robotics in engineering is promising, driven by continuous advancements in AI, machine learning, and sensor technologies. Collaborative robots, or cobots, that work alongside human workers are becoming increasingly popular. These robots are designed to be friendly and intuitive, enhancing productivity without displacing the workforce.

Moreover, the role of robotics in sustainability is gaining prominence. Automated systems can optimize resource usage, reduce waste, and facilitate environmentally friendly practices. As engineers increasingly focus on sustainable practices, robotics will play an essential role in meeting these goals.

Conclusion

Robotics is a transformative force in modern engineering, reshaping how industries operate and innovate. While challenges exist, the benefits of increased efficiency, precision, and safety underscore the importance of robotics in advancing engineering disciplines. As technology continues to evolve, the potential for robotics to influence engineering is boundless, promising a future where human ingenuity and robotics work hand in hand to solve complex problems and drive societal progress.